Roll Jet Dryer/

SRJ-125 (SRJ-100)

This machine dries the raw, moisture-heavy veneer after peeling on the lathe. Taihei’s proprietary technology performs rolling without bending. This eliminates inconsistent pressures, improves veneer yield, eliminates clogging, and reduces waving and cracking. As well, the unit configuration significantly shortens installation times.

Standard Specifications

- Feed roll size

- Φ101.6mm×6,200mmL(5,000mmL)

- Heating section length

- 2,000mm

- Decks

- 6 Decks

- Heat source

- Gas burner/Steam

POINT

- Low energy and efficient, high-humidity drying

- Proprietary rolling technology reduces bending and deformation

- Systematize processes with auto feeder and sorting stacker

-

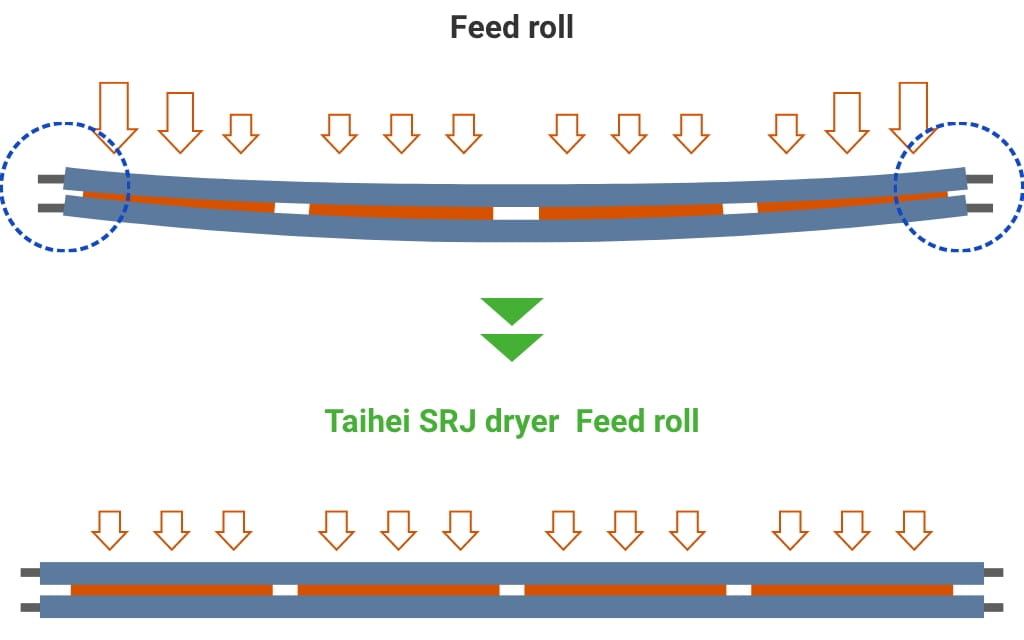

Proprietary technology reduces bending(Proprietary "cRu" Roll Support System)

Uses proprietary technology that helps keep the roll from bending under its own weight and improve veneer feed performance. In conventional dryers the feed rolls bend under their own weight, which causes inconsistencies in veneer thickness. In the Roll Jet Dryer, feed roll bending is reduced, which can help eliminate inconsistence thicknesses and improve yield.

-

Heating/cooling section units

In conventional machines, the heating and cooling sections are assembled and installed on site to fit the installation location. With our model, these sections are shipped as fully assembled units. Building the units in our own factory not only increases product quality and precision, but also dramatically reduces the time required for installation, which traditionally has been three to four months.

Options

Type VF-5(4) Vacuum Pre-feeder

Veneer suctioning locations can be changed to match the feeder cycle.

Using a vacuum generator eliminates the need for large-capacity dust collectors.

Workers do not need to insert the veneer by hand, so everything can be handled by a single operator.

Can produce output in 3.3 second cycles for 2,540 mm boards.

Uses detection system to detect when two panels are inserted. When two panels are detected, the system stops at that location until one of the panels is removed, but in other locations the feeder continues to insert panels, thus avoiding any slowdown in the panel fill rate.

Standard Specifications

- Gripper length

- 1,000mm

- Gripper pitch

- 1,200mm

- Feeder cycle

- Min. time of 3.3 s (panel length of 2,540 mm) per stage